Call Us08045800995

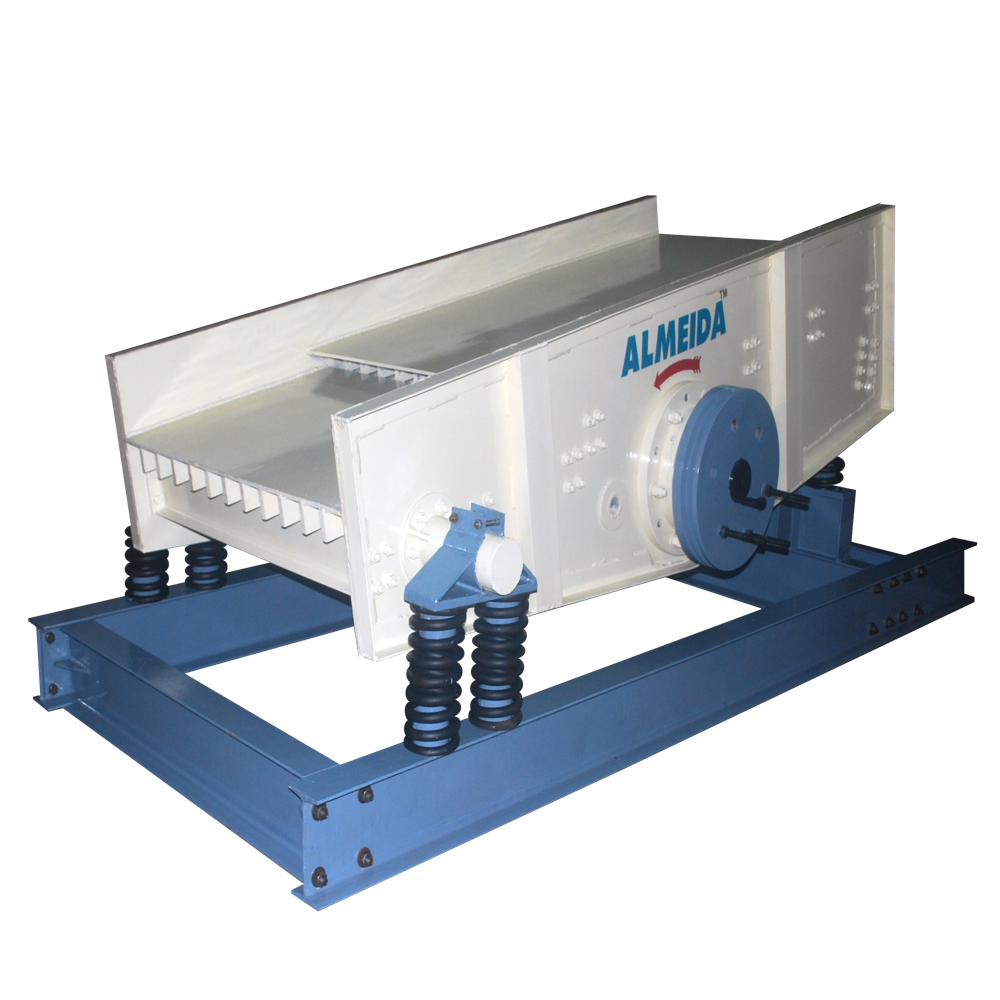

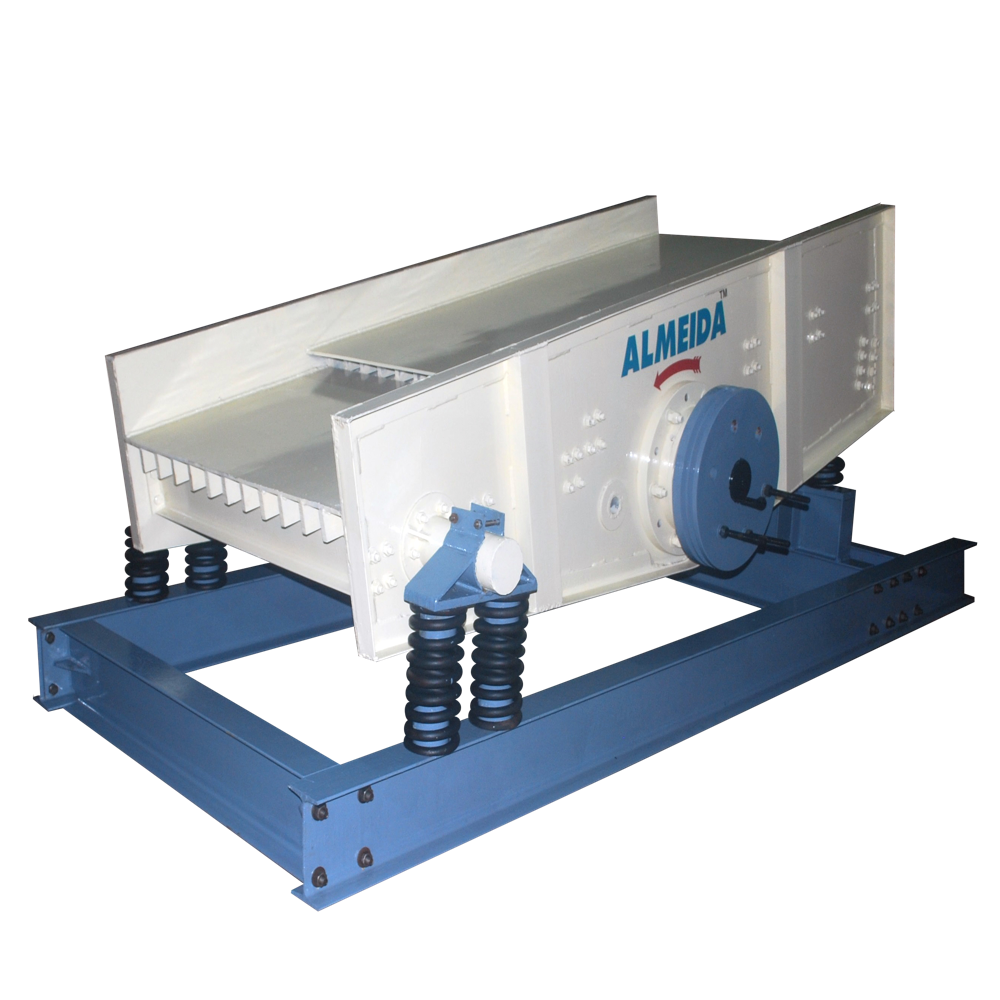

Industrial Grizzly Feeders

Product Details:

- Type Grizzly Feeders

- Material Mild Steel

- Computerized No

- Automatic Grade Automatic

- Warranty 12 Month

- Click to view more

X

Industrial Grizzly Feeders Price and Quantity

- 1 Unit

Industrial Grizzly Feeders Specification

- No

- Grizzly Feeders

- 12 Month

- Mild Steel

- Automatic

Industrial Grizzly Feeders Trade Information

- 10 Unit Per Month

- 1-3 Week

Product Description

Acclaimed in the market for quality, our name has been considered as one of the prominent manufacturers, suppliers and exporters of Grizzly Feeders. These feeders are designed from certified quality raw materials to ensure longevity and reliability. There are several different models of stone crushers are available with us to crush soft stones like limestone etc and hard stones like granite etc. Our offered stone crushers are highly efficient and have large stone crushing capacity per hour. These machines are also available in customized range so that our valuable clients can purchase these as per their specifications and requirements. We offer these feeders at the affordable price range to our prestigious customers.

Industrial Grizzly Feeding Equipment Features:

1. Optimum structural design

2. Safe and simple to use

3. Impervious to adverse conditions

4. Excellent tensile strength

Grizzly Feeder Applications:

1. Mining: Grizzly feeding equipment are extensively used in mining operations to handle large feed sizes of ore and minerals. They are placed before primary crushers to remove undersized material and improve the efficiency of the crushing process.

2. Quarrying: In quarrying operations, grizzly feeders are employed to separate oversized rocks and stones from the incoming feed material. This helps in preventing damage to downstream equipment such as crushers and screens.

3. Construction: These equipments are used in construction sites to handle aggregates, gravel, and other bulk materials. They ensure a steady flow of material to crushers, screens, or conveyors, enhancing productivity and efficiency.

4. Recycling: Grizzly feeders play a crucial role in recycling facilities by separating and feeding bulky materials such as concrete, asphalt, and demolition waste. They help in the efficient processing of recycled materials for further use.

5. Coal Handling Plants: Grizzly feeding equipements are utilized in coal handling plants to handle large-sized coal and prevent oversized coal from entering the crushing equipment. This helps in maintaining the efficiency and reliability of the coal processing system.

6. Steel Production: In steel manufacturing plants, grizzly feeders are employed to handle iron ore, sinter, and other raw materials. They ensure a uniform feed to the processing equipment, such as blast furnaces and crushers, optimizing production efficiency.

7. Aggregate Processing: Grizzly feeders are commonly used in aggregate processing plants to separate and control the flow of various sizes of rocks, gravel, and sand. They are placed ahead of crushers and screens to remove oversized material and improve the quality of the final product.

8. Forestry and Biomass: In forestry and biomass industries, grizzly feeders are utilized to handle logs, wood chips, and other bulky materials. They help in the efficient processing of biomass for applications such as wood pellet production and energy generation.

9. Chemical and Pharmaceutical: These equipments find applications in chemical and pharmaceutical industries for handling bulk solids such as powders, granules, and aggregates. They ensure a consistent and controlled feed of materials to various processing equipment.

Grizzly Feeder FAQ:

Q. How does a grizzly feeder work?

Ans: Grizzly feeders work by utilizing vibration to move and separate large-sized materials from the feed stream. The vibrating motion of the feeder causes the material to move across the grizzly bars or pan, allowing smaller particles to pass through while oversized materials are scalped and directed to the discharge end.

Q. What are the benefits of using a grizzly feeder?

Ans: Some benefits of using a grizzly feeder include:

- Improved efficiency by removing oversized materials before they reach downstream equipment.

- Protection of crushers, screens, and conveyors from damage caused by large rocks or debris.

- Enhanced safety by preventing oversized materials from causing blockages or jams in processing equipment.

- Control over the feed rate and consistency of material flow for optimized processing operations.

Q. What types of materials can be handled by a grizzly feeder?

Ans: These equipments are suitable for handling a wide range of materials, including ores, minerals, coal, aggregates, construction and demolition waste, biomass, chemicals, and more. They are designed to handle large-sized materials typically ranging from heavy rocks to bulky industrial materials.

Q. Where are grizzly feeders commonly used?

Ans: These equipments find applications in various industries such as mining, quarrying, construction, recycling, steel production, forestry, chemical processing, and pharmaceuticals. They are utilized wherever there is a need to handle and process large-sized materials efficiently.

Q. How do you select the right grizzly feeder for a specific application?

Ans: When selecting a grizzly feeder, factors to consider include the type and size of material to be handled, the required feed rate, the size of downstream equipment, space constraints, and environmental conditions. Consulting with equipment manufacturers or specialists can help in choosing the appropriate grizzly feeder for a particular application.

Q. How do you maintain a grizzly feeder?

Ans: Maintenance of a grizzly feeder typically involves regular inspection, cleaning, lubrication of moving parts, and replacement of worn-out components such as grizzly bars, springs, and bearings. Following the manufacturer's maintenance guidelines and scheduling routine inspections can help in ensuring the optimal performance and longevity of the equipment.

Q. Can a grizzly feeder be customized for specific requirements?

Ans: Yes, grizzly feeding equipment can be customized to meet specific requirements such as feed capacity, material size, feeding angle, and installation configuration. Equipment manufacturers often offer customization options to tailor the design of the grizzly feeder according to the needs of the application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free