Call Us08045800995

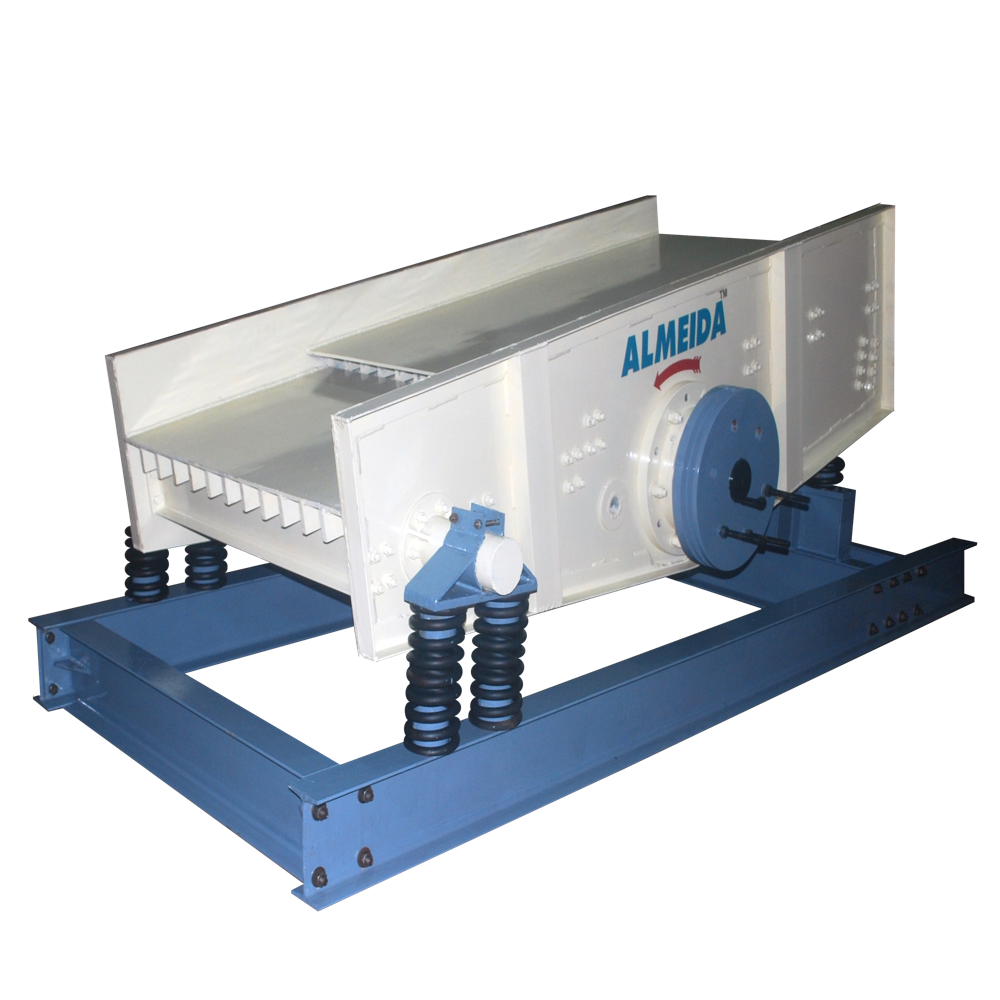

Vibrating Feeders

Product Details:

- Type Vibrating Feeders

- Material Mild Steel

- Computerized No

- Automatic Grade Semi-Automatic

- Warranty 12 Month

- Click to view more

X

Vibrating Feeders Price and Quantity

- 1 Unit

Vibrating Feeders Specification

- Vibrating Feeders

- 12 Month

- No

- Semi-Automatic

- Mild Steel

Vibrating Feeders Trade Information

- 10 Unit Per Month

- 1-3 Week

- All India

Product Description

Since our establishment in 1998, we have been manufacturing, supplying and exporting a large gamut of Vibrating Feeders which are highly utilized in construction industry, glass industry, foundry industry, chemical industry and landfill reclamation. Our team of engineers have designed these by using supreme quality raw material so that these can work efficiently in adverse conditions. Offered feeders are the best option to transport bulk materials from one place to another at an appropriate feed rate. These machines are acclaimed for their rugged design, durability, reliability, working efficiency and high loading capacity. Offered feeders are available in various sizes and specifications as per the demands & requirements of clients at economical price range.

Vibration Feeder Machine Features:

- Designed to accommodate heavy headloads

- Feed rate can be adjusted by variable capacity control

- Works in minimum downtime

- Requires low maintenance

- Can be easily installed

FAQ:

Q. What is a vibrating feeder?

Ans: A vibrating feeder is a device used to transport and dispense bulk materials, granular materials, or parts in a controlled manner through vibration. It consists of a vibrating base or tray that moves materials along a conveying path.

Q. How does a vibrating feeder work?

Ans: The vibrating feeder uses electromagnetic vibrations or mechanical vibrations to move materials. When activated, the feeder's vibrating motor or electromagnet generates vibrations that cause the material to move in a forward direction. The material flow rate can be controlled by adjusting the vibration intensity or frequency.

Q. What are the main applications of vibrating feeders?

Ans: Vibrating feeders are used in various industries for a wide range of applications, such as in mining, construction, food processing, pharmaceuticals, chemical processing, and manufacturing. They are commonly used to feed bulk materials to crushers, conveyors, or other processing equipment.

Q. What are the advantages of using vibrating feeders?

Ans: Vibrating feeders offer several benefits, including precise material control, high feed rates, reduced material handling, uniform material distribution, and the ability to handle a variety of materials. They are also relatively low-maintenance and easy to operate.

Q. What types of vibrating feeders are available?

Ans: There are different types of vibrating feeders, including electromagnetic vibrating feeders and electromechanical vibrating feeders. Electromagnetic feeders use electromagnetic coils to generate vibrations, while electromechanical feeders use electric motors with eccentric weights to create vibrations.

Q. How do I select the right vibrating feeder for my application?

Ans: Choosing the right vibrating feeder depends on factors such as the material being handled, the required feed rate, the characteristics of the material (e.g., particle size, density), the environment, and any specific process requirements. Consulting with a knowledgeable supplier or engineer can help you select the most suitable feeder for your needs.

Q. How do I maintain a vibrating feeder?

Ans: Regular maintenance is essential to keep the vibrating feeder operating optimally. Maintenance tasks may include cleaning, lubrication, inspection of electrical connections, and checking for any signs of wear or damage. Refer to the manufacturer's guidelines and recommendations for specific maintenance procedures.

Q. Are vibrating feeders safe to use?

Ans: Vibrating feeders are generally safe when operated and maintained correctly. However, users should follow safety guidelines and precautions provided by the manufacturer. Additionally, operators should be trained on how to use the equipment safely.

Q. Can vibrating feeders handle fragile materials?

Ans: Yes, vibrating feeders can be adapted to handle fragile materials by adjusting the vibration intensity and using appropriate tray designs to minimize impact and abrasion on the materials.

Q. Can vibrating feeders be customized for specific needs?

Ans: Yes, many manufacturers offer customization options for vibrating feeders, such as material handling capacities, tray designs, and control options. This allows users to tailor the equipment to their specific requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free