Call Us08045800995

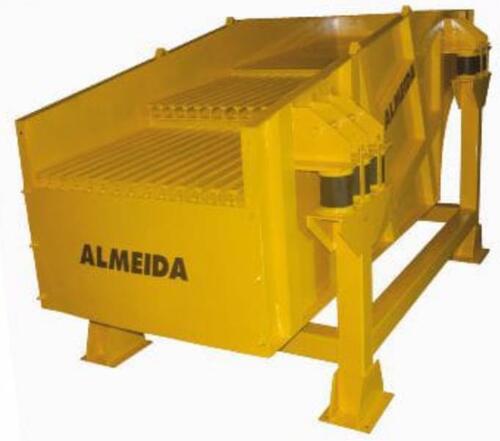

Grizzly Feeders

Product Details:

- Type Grizzly Feeders

- Computerized No

- Automatic Grade Automatic

- Click to view more

X

Grizzly Feeders Price and Quantity

- 1 Unit

Grizzly Feeders Specification

- Grizzly Feeders

- Automatic

- No

Grizzly Feeders Trade Information

- 10 Unit Per Month

- 1-3 Week

- All India

Product Description

We are highly acknowledged across the market as one of the progressive & prominent manufacturers, suppliers and exporters of Grizzly Feeders. These feeders are designed for crushing lumpy materials at controlled feed rate. Basically, the function of these feeder machines are based on reciprocating movement that is further generated by eccentric driving mechanism. Usually, these machines serve their purposes in sand processing plants. Our highly skilled personnel manufacture these Reciprocating Feeders by utilizing superlative materials to provide durability, strength and efficiency, which s why our offered machines are admired in almost all material handling industries. Our precious clients can place the order for these feeders in bulk at the market leading prices.

Grizzly Feeder Features:

1. Consistent performance

2. Less operating cost

3. Highly productive

4. Long operational life

5. Easy to install and maintain

Grizzly Feeding Machine Applications:

1. Mining: Grizzly feeders are extensively used in the mining industry to feed large chunks of ore into primary crushers. They can handle a variety of materials, including coal, iron ore, copper, gold, and aggregates.

2. Quarrying: In quarry operations, grizzly feeders play a crucial role in processing raw materials such as limestone, granite, and sandstone. They efficiently separate oversized rocks and debris from the material stream, preventing damage to downstream equipment.

3. Recycling: Grizzly feeding machines are employed in recycling facilities to handle bulky materials such as concrete, asphalt, and demolition waste. By removing oversized debris, they ensure the smooth operation of recycling equipment like crushers and screens.

4. Construction: These machines are utilized in construction projects to process large volumes of aggregates, gravel, and sand. They help in segregating oversized rocks and ensuring a consistent feed to crushers and screening plants.

5. Aggregate Production: These machines are integral components in aggregate production plants, where they efficiently handle various materials ranging from blasted rock to gravel and sand. They aid in controlling the flow of material and removing unwanted contaminants.

6. Coal Handling: In coal mining and thermal power plants, grizzly feeders are employed to handle coal and prevent oversized coal chunks from entering the crushing and conveying systems. This improves the efficiency and safety of coal handling operations.

7. Metallurgy: Grizzly feeders find applications in metallurgical plants for handling ores, minerals, and other raw materials. They ensure a uniform feed to crushers, mills, and processing equipment, optimizing the overall efficiency of the production process.

8. Waste Management: Grizzly feeding machines are utilized in waste management facilities to process bulky waste materials and separate recyclable materials from non-recyclables. They aid in improving the sorting process and reducing landfill waste.

9. Forestry and Agriculture: Grizzly feeders are sometimes used in forestry and agricultural operations for handling materials such as wood chips, bark, and agricultural products. They help in processing and transporting these materials efficiently.

Grizzly Feeder FAQ:

Q. How does a grizzly feeder work?

Ans: Grizzly feeders work by vibrating the screening surface, which allows smaller materials to pass through while larger materials are separated and discharged off the end of the feeder. This helps in controlling the feed rate and protecting downstream equipment from damage.

Q. What are the main components of a grizzly feeder?

Ans: The main components of a grizzly feeder include the vibrating frame, screening surface (grate or bars), drive mechanism (electric motor and gearbox), support springs, and isolation mounts. Some feeders may also have adjustable mechanisms to control the feed rate and amplitude of vibrations.

Q. What materials can be processed with a grizzly feeder?

Ans: Grizzly feeders can handle a wide range of materials including ores, minerals, aggregates, coal, wood chips, construction and demolition waste, recycled materials, and more. The size and design of the feeder may vary depending on the specific application and material characteristics.

Q. What are the advantages of using a grizzly feeder?

Ans: Some advantages of using a grizzly feeding machine include:

- Efficient removal of oversized materials, improving downstream processing efficiency.

- Protection of crushers and other processing equipment from damage caused by large rocks or foreign objects.

- Control over the feed rate and distribution of materials, resulting in better process control and product quality.

- Reduction of downtime and maintenance costs by preventing equipment damage and blockages.

Q. How do you size a grizzly feeder for a specific application?

Ans: Sizing a grizzly feeding machine involves considering factors such as the feed material size distribution, feed rate, desired capacity, and the characteristics of downstream processing equipment. Manufacturers typically provide guidelines and technical support to help users select the appropriate feeder size and configuration for their application.

Q. What maintenance is required for a grizzly feeder?

Ans: Regular maintenance tasks for a grizzly feeding machine may include lubrication of bearings and drive components, inspection and replacement of wear parts (such as grizzly bars or screens), checking for loose bolts or connections, and monitoring the overall condition of the feeder for signs of wear or damage.

Q. Can a grizzly feeder be customized for specific applications?

Ans: Yes, these machines can often be customized to meet specific application requirements. This may include modifications to the screening surface design, adjustments to the amplitude and frequency of vibrations, installation of special liners or wear-resistant materials, and integration with other equipment or control systems.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free