Call Us08045800995

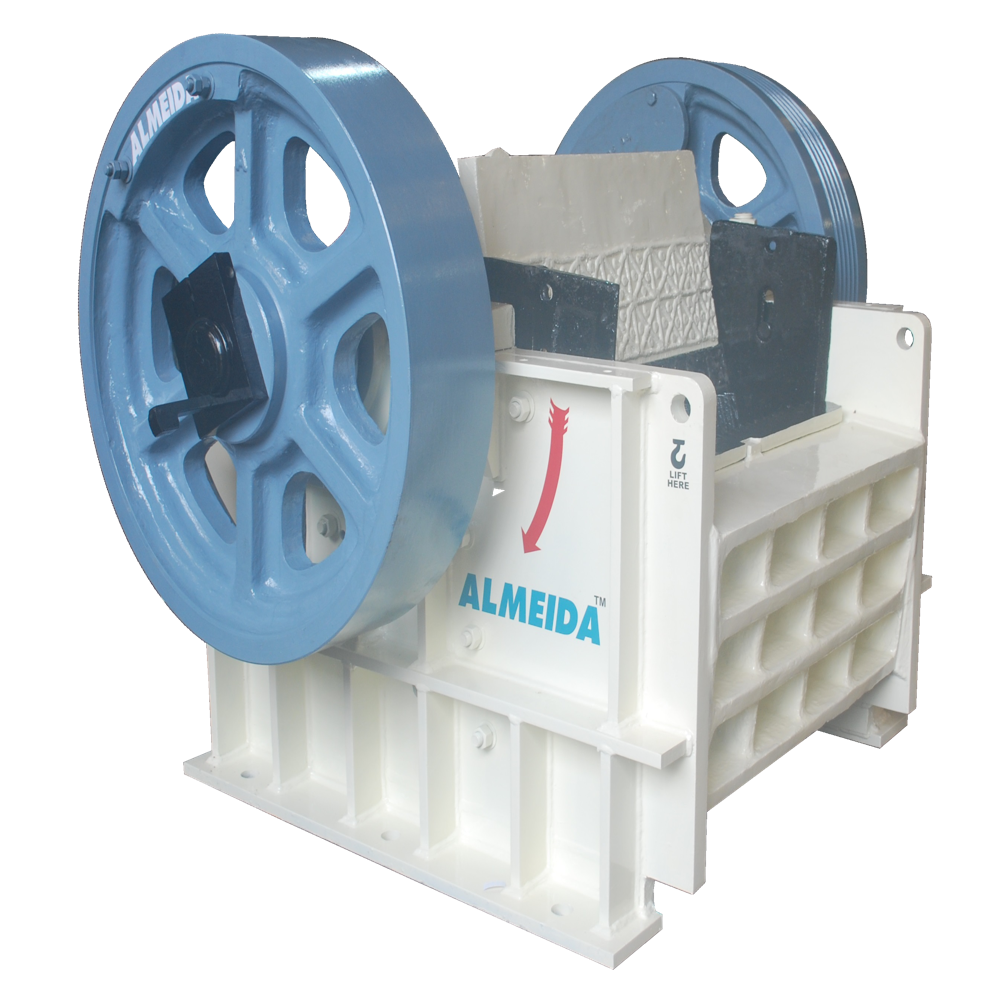

Primary Jaw 200TPH

Product Details:

- Product Type Jaw Crusher

- General Use Industrial

- Material Stainless Steel

- Computerized No

- Automatic Yes

- CNC Or Not Normal

- Control System PLC Control

- Click to view more

X

Primary Jaw 200TPH Price and Quantity

- 1 Unit

Primary Jaw 200TPH Specification

- No

- Jaw Crusher

- PLC Control

- Industrial

- Stainless Steel

- Yellow

- Normal

- Yes

Primary Jaw 200TPH Trade Information

- 10 Unit Per Month

- 1-3 Week

- All India

Product Description

Siddharth Engineering Co is one of the leading manufacturers and suppliers of high-speed Primary Jaw 200TPH that is designed and developed as per the engineering standards that give high working efficiency and durability. It is capable to produce crushed products in large quantities up to the capacity of 200 tons per hour. This mining-grade machine requires a standardized alternating voltage of 220 to 440 volts with a frequency of 50 to 60 Hertz. Primary Jaw 200TPH availed by us has a flat flanged base that gives high stability during operation to withstand vibrations.

High-Efficiency Crushing Solution

Engineered to handle various industrial materials, the Primary Jaw 200TPH delivers consistent performance in high-volume environments. Its stainless steel build maximizes lifespan, while the automated PLC control system streamlines workflow and reduces labor costs.

Stainless Steel Durability

Constructed from high-grade stainless steel, this jaw crusher is resistant to corrosion and wear, which is crucial for continuous industrial use. The yellow color enhances visibility, supporting safe operation in busy work environments.

FAQs of Primary Jaw 200TPH:

Q: How does the PLC control system improve the operation of the Primary Jaw 200TPH?

A: The PLC control system automates and optimizes the machines operations, allowing for precise control, monitoring, and adjustment of parameters. This results in increased productivity, reduced downtime, and enhanced safety during use.Q: What materials can be processed using the Primary Jaw 200TPH?

A: This jaw crusher is suitable for a variety of industrial materials, including ores, aggregates, and other hard materials commonly found in mining, construction, and aggregate processing industries.Q: When is this crusher most beneficial for industrial operations?

A: The Primary Jaw 200TPH is most beneficial when consistent, high-volume material reduction is requiredideal for industries needing efficient primary crushing to support downstream processing applications.Q: Where is this machine typically used?

A: It is widely utilized in industrial settings such as mining sites, construction projects, aggregate plants, and material processing facilities, especially where high throughput and robust machinery are essential.Q: What is the process for installing and using the Primary Jaw 200TPH?

A: Installation involves securing the crusher on a stable base, connecting it to the power source, and configuring the PLC system according to operational needs. Once set up, the unit operates automatically, with periodic maintenance to ensure optimal performance.Q: How does automatic operation benefit the end-user?

A: Automatic operation minimizes manual intervention, increases efficiency, and reduces the likelihood of operational errors, leading to improved safety and productivity in industrial workflows.Q: What are the advantages of the stainless steel construction?

A: Stainless steel provides resilience against rust, wear, and heavy use, extending the machines service life and maintaining consistent performance even in harsh industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese