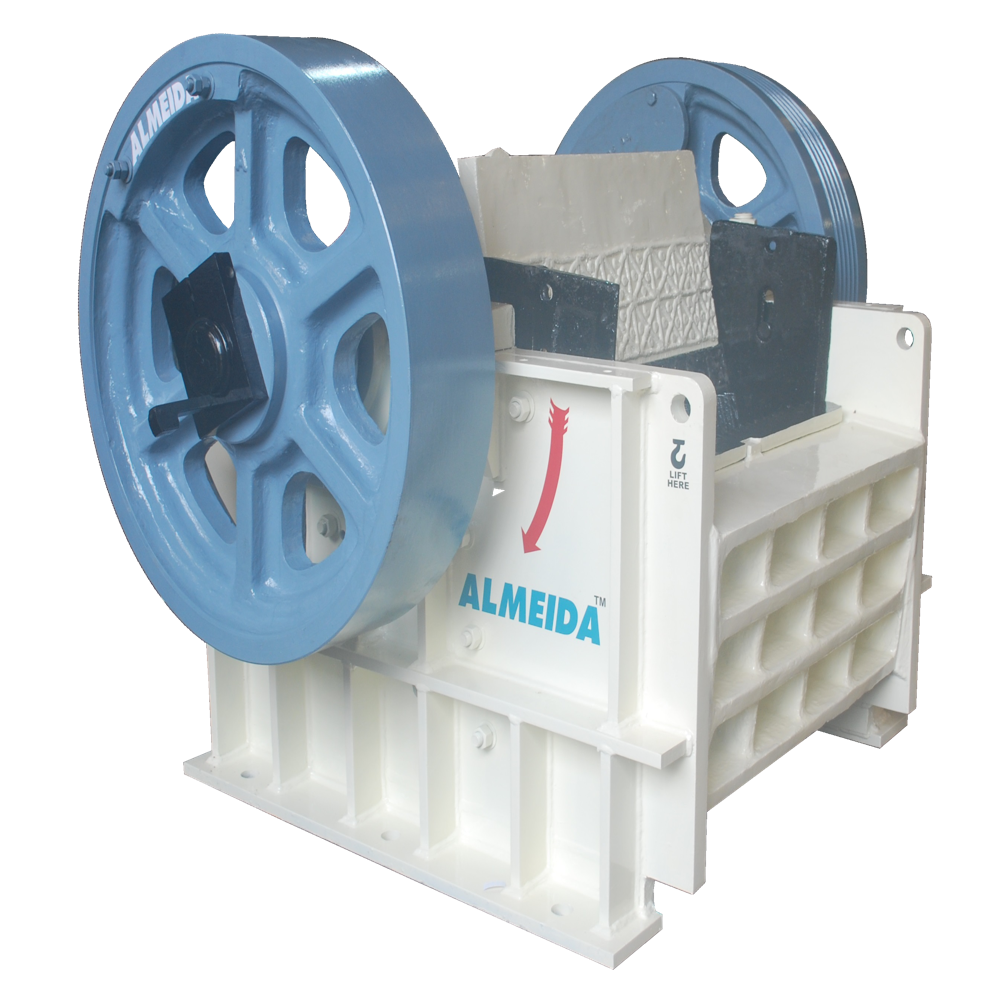

Single Toggle Jaw Crusher

Product Details:

- Product Type Jaw Crushing Machine

- General Use Industrial

- Material Stainless Steel

- Computerized No

- Automatic Yes

- CNC Or Not Normal

- Control System PLC Control

- Click to view more

Double Toggle Jaw Crusher Price and Quantity

- 1 Unit

Double Toggle Jaw Crusher Specification

- Jaw Crushing Machine

- PLC Control

- White

- Industrial

- Yes

- 1 year

- Normal

- Stainless Steel

- No

Double Toggle Jaw Crusher Trade Information

- 10 Unit Per Month

- 1-3 Week

- All India

Product Description

Owing to profound knowledge of the industry, our company is regarded as one of the reliable manufacturers, suppliers and exporters of Double Toggle Jaw Crusher. We design these machines to crush the hard stones and soft stones into smaller pieces that are further used to put on railway tracks, near river banks etc. Apart from this, these machines can also be employed for crushing glass, coal, rocks and other hard materials. Offered machines are highly appreciated for their advanced mechanism, strong structure, premium quality, uninterrupted operation, overloading protection system and high efficiency. Our prestigious clients can avail these mahcines from us at the most competitive prices.

Features ofDouble Toggle Jaw Crushing Machine:

- Strong and reliable structure

- Designed to perfection

- Maximum operational life

- Minimum maintenance

- Highly efficient

- Works with high rotation per minute hence, provides high output

Double Toggle Jaw Crusher Specifications:

| Size | 350x200 | 400x250 | 500x250 | 600x300 | 600x150 | 900x150 | 1050x150 | 600x375 | 750x375 | 750x 450 | 900x600 | 1000x750 |

| A | 1110 | 1310 | 1400 | 1610 | 1375 | 1360 | 1360 | 1820 | 1755 | 1910 | 2050 | 2180 |

| B | 1110 | 1390 | 1480 | 1650 | 1365 | 1500 | 1500 | 1720 | 1700 | 2065 | 2410 | 2605 |

| C | 770 | 825 | 980 | 1020 | 980 | 1020 | 1020 | 1020 | 1020 | 1230 | 1240 | 1220 |

| D | 1150 | 1260 | 1660 | 1735 | 1660 | 1840 | 1960 | 1735 | 1710 | 1720 | 1905 | 2135 |

| E | 990 | 1045 | 1430 | 1555 | 1475 | 1800 | 1890 | 1575 | 1640 | 1656 | 1895 | 2065 |

| F | 720 | 800 | 905 | 1035 | 1035 | 1320 | 1470 | 1035 | 1270 | 1270 | 1600 | 1690 |

| G | 725 | 980 | 990 | 1140 | 875 | 990 | 990 | 1200 | 1180 | 1450 | 1790 | 1995 |

| Power | 20 | 25 | 30 | 50 | 30 | 50 | 60 | 50 | 60 | 75 | 100 | 125 |

| RPM | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 275 | 275 | 265 | 265 |

| Feed Size | 175 | 225 | 225 | 275 | 125 | 124 | 125 | 350 | 350 | 450 | 600 | 760 |

| WT (Tons) | 2.1 | 2.9 | 3.8 | 6.7 | 3.9 | 5.5 | 6.5 | 7.2 | 8.8 | 10.5 | 17.2 | 24.0 |

Crushing Capacity in Cubic MTS /HR

| 12 | 2.6 | 5.2 | 9.9 | - | 12.0 | 16.0 | 21.0 | - | - | - | - | - |

| 20 | 2.9 | 5.8 | 10.5 | 14.2 | 13.2 | 17.5 | 23.0 | - | - | - | - | - |

| 25 | 3.2 | 6.4 | 11.8 | 15.4 | 14.5 | 19.0 | 25.5 | 19.0 | - | - | - | - |

| 32 | - | 7.1 | 13.0 | 17.0 | - | - | - | 23.0 | - | - | ||

| 40 | - | 8.5 | 15.0 | 19.0 | - | - | - | 26.0 | 32 | - | - | - |

| 50 | - | - | 17.0 | 22.0 | - | - | - | 29 | 37 | 45 | - | - |

| 75 | - | - | - | 26.0 | - | - | - | 35 | 144 | 54 | 70 | - |

| 100 | - | - | - | - | - | - | - | 41 | 52 | 63 | 85 | 115 |

| 125 | - | - | - | - | - | - | - | 47 | 60 | 72 | 98 | 140 |

| 150 | - | - | - | - | - | - | - | - | - | - | 112 | 170 |

| 200 | - | - | - | - | - | - | - | - | - | - | 150 | 200 |

| 250 | - | - | - | - | - | - | - | - | - | - | 185 | 290 |

Advanced Automation and PLC Control

Benefit from seamless operation with our integrated PLC control system. This jaw crushers automatic grade ensures consistent performance and reduces the need for manual intervention during industrial usage. Enhanced automation improves productivity and safety for your workforce.

Durable Materials and Elegant Design

Manufactured using premium iron and stainless steel, this crusher offers excellent resistance to wear and tear. Its stylish grey and white color options fit various industrial environments while ensuring robust functionality and prolonged service life.

FAQs of Single Toggle Jaw Crusher:

Q: How does the PLC control system enhance the performance of the Single Toggle Jaw Crusher?

A: The PLC control system automates operational settings, ensuring accurate and consistent crushing cycles while minimizing manual adjustments, thereby enhancing productivity and reducing downtime.Q: What materials are used to manufacture this jaw crusher?

A: This crusher is constructed from high-quality iron and stainless steel, ensuring durability and excellent resistance to industrial wear and corrosion.Q: When should this crusher be serviced to maintain optimal efficiency?

A: It is recommended to follow a routine maintenance schedule every six months or as specified in the user manual, ensuring all components are inspected and lubricated for uninterrupted operation.Q: Where can this Single Toggle Jaw Crusher be utilized?

A: This crusher is ideal for use in various industrial sectors, such as mining, construction, and material processing plants, thanks to its sturdy build and automated controls.Q: What is the general process for operating the crusher?

A: To operate, simply load the material and set desired parameters via the PLC panel. The automated system manages the crushing cycle, ensuring efficient throughput and safe operation.Q: How can industrial users benefit from choosing this jaw crusher?

A: Users benefit from its reliable automatic operations, low maintenance requirements, robust construction, and the assurance of a one-year warranty, making it cost-effective for demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese