Call Us08045800995

Vertical Shaft Impactor Crusher

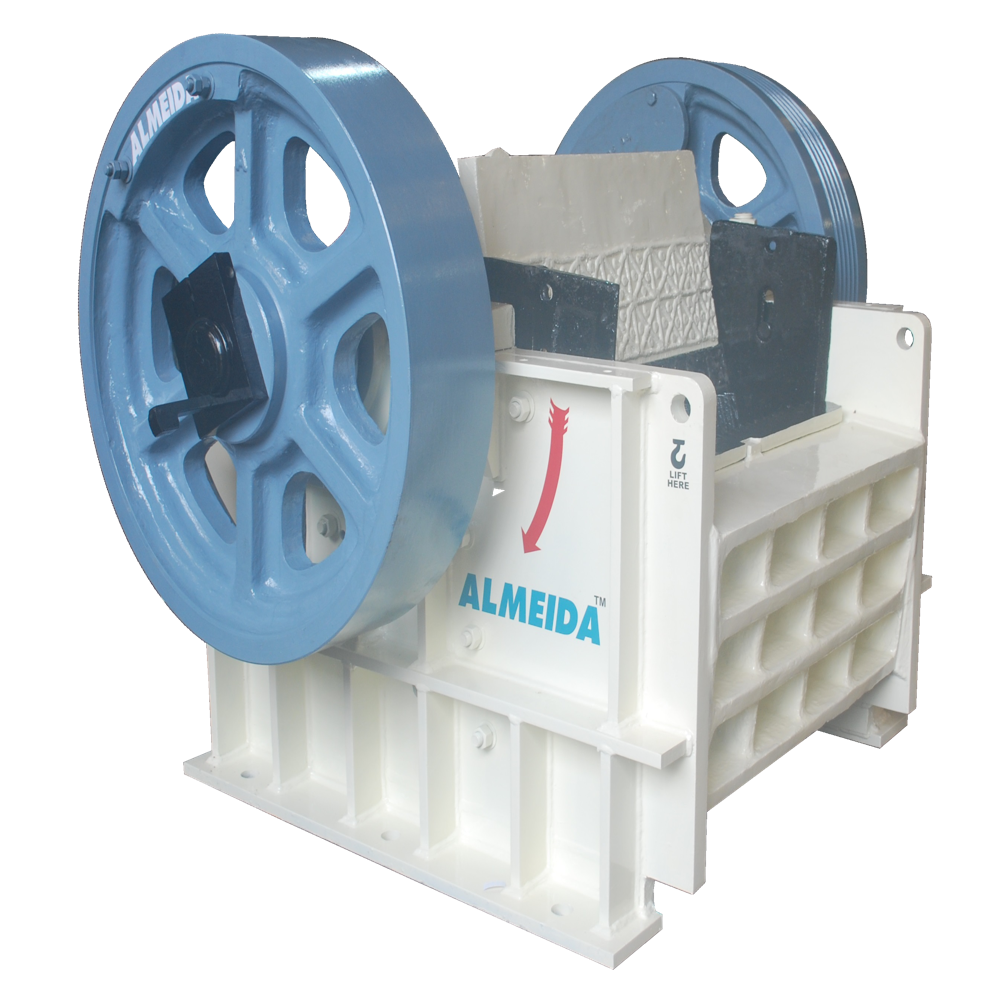

Product Details:

- Product Type Impactor Crusher

- General Use Industrial

- Material Stainless Steel

- Computerized No

- Automatic Yes

- CNC Or Not Normal

- Control System PLC Control

- Click to view more

X

Vertical Shaft Impactor Crusher Price And Quantity

- 1 Unit

Vertical Shaft Impactor Crusher Product Specifications

- Yes

- Industrial

- Yellow

- 1 year

- PLC Control

- Impactor Crusher

- No

- Stainless Steel

- Normal

Vertical Shaft Impactor Crusher Trade Information

- 10 Unit Per Month

- 1-3 Week

- All India

Product Description

Enlisted in the line of reputed companies, we are known as a best manufacturer, supplier and exporter of Horizontal Shaft Impactor Crusher. In our manufacturing unit, these are made in supreme quality raw materials to provide high tensile strength and longer shelf life. Offered product is widely used to break the hard materials through the hammer connected with a rotor, which is aligned along the horizontal axis. These impact crushers are available in varied models that are further having varied throughput capacity. Moreover, owing to their durable construction and sudden-change wedge system, these work with extreme efficiency. Clients can place the order for these Horizontal Shaft Impactor in bulk to us at the nominal price range.

Features of Horizontal Shaft Impact Crusher:

1. Rotor speed can be altered, depending upon the gradation requirements

2. Both electric motor and diesel motor can be utilized for operating these impactors

3. Minimum power consumption

4. Wear parts can be easily replaced

5. Can crush the hard materials in less time

FAQ:

Q. What is a Horizontal Shaft Impactor (HSI) crusher?

Ans: A Horizontal Shaft Impactor (HSI) crusher is a type of crushing equipment used in various industries to reduce the size of large rocks, minerals, or other materials. It utilizes a horizontal shaft that rotates rapidly to break the material into smaller pieces.

Q. How does an Horizontal Shaft Impact Crusher work?

Ans: The HSI crusher works by impacting the material with hammers or blow bars fixed to the rotor. As the rotor rotates at high speed, the material is fed into the crushing chamber, and the kinetic energy from the rotating hammers causes the material to break into smaller pieces upon impact.

Q. What are the advantages of using an HSI crusher?

Ans: Some advantages of using an HSI crusher include:

1. High reduction ratio: HSI crushers can achieve high reduction ratios, making them suitable for various crushing applications.

2. Versatility: They can handle a wide range of materials, including soft to medium-hard rocks and minerals.

3. Low operating and maintenance costs: HSI crushers generally have lower operational and maintenance costs compared to other types of crushers.

4. Cubical-shaped product: HSI crushers produce cubical-shaped end products, which are desirable in many applications.

Q. What types of materials can an HSI crusher handle?

Ans: HSI crushers are commonly used for crushing a variety of materials, including limestone, granite, gravel, concrete, asphalt, and other similar materials.

Q. What is the difference between HSI and VSI (Vertical Shaft Impactor) crushers?

Ans: The primary difference between HSI and VSI crushers is the type of crushing action they perform. While HSI crushers use impact force to break the material, VSI crushers use a high-speed rotor and anvils for impact crushing. VSI crushers are more suitable for shaping the end product and producing fine aggregates, while HSI crushers are better suited for primary and secondary crushing of larger materials.

Q. What are the key components of an HSI crusher?

Ans: The main components of an HSI crusher include:

1. Rotor: The horizontal shaft that holds the hammers or blow bars and rotates to impact the material.

2. Blow bars or hammers: Attached to the rotor, these components deliver the crushing force to the material.

3. Crushing chamber: The area where the material is fed and crushed.

4. Aprons: These are adjustable impact aprons that control the size of the output material.

5. Hopper: The container that holds the incoming material before it enters the crushing chamber.

Q. How to maintain an HSI crusher?

Ans: Proper maintenance is essential to ensure the efficient and reliable operation of an HSI crusher. Regular inspection, lubrication, and replacement of wear parts (such as blow bars or hammers) are crucial. Its also important to follow the manufacturers maintenance schedule and guidelines for optimal performance.

Q. What safety precautions should be taken while operating an HSI crusher?

Ans: Operators should follow safety guidelines and wear appropriate personal protective equipment (PPE) while operating the crusher. Its important to keep hands and other body parts away from moving components during operation and to lock out/tag out the crusher during maintenance or repair work.

Q. What capacity range do Horizontal Shaft Impact Crushers offer?

Ans: HSI crushers come in various sizes and can offer a wide range of capacities depending on factors such as the feed material size, the type of material being crushed, and the required final product size. Capacities can range from a few hundred tons per hour to several thousand tons per hour.

Advanced PLC Automation

Our Vertical Shaft Impactor Crusher is outfitted with a sophisticated PLC control system, ensuring automated and precise operation. This functionality simplifies workflow, reduces manual intervention, and optimizes productivity for industrial users. With the push of a button, operators gain full control, resulting in consistent output and fewer operational errors.

Durable Stainless Steel Construction

Manufactured from high-grade stainless steel, this crusher offers exceptional durability and resistance to corrosion. Its robust structure is designed to withstand the demanding environments of industrial processing, promising minimal maintenance and long-lasting performance even under heavy-duty usage conditions.

FAQs of Vertical Shaft Impactor Crusher:

Q: How does the Vertical Shaft Impactor Crusher operate?

A: The crusher works by propelling materials against a high-speed rotor, causing them to be crushed and shaped upon impact with internal anvils. Its PLC control system ensures that the operation remains fully automatic and efficient, reducing the need for manual adjustments.Q: What are the primary benefits of using this automatic crusher in industrial settings?

A: Key advantages include improved material consistency, reduced labor through automated PLC control, and high output with minimal maintenance thanks to its robust stainless steel construction. These features collectively help industrial operations scale up productivity.Q: When is the ideal time to deploy this machine in your process line?

A: This crusher is best utilized when there is a need for high-quality, cubical-shaped aggregate production, especially during material processing stages that demand uniformity and high throughput in an automated industrial setting.Q: Where is this Vertical Shaft Impactor Crusher manufactured and supplied?

A: The crusher is manufactured and exported from India, serving as a reliable choice for manufacturers, suppliers, and exporters across various industrial sectors in India and abroad.Q: What is involved in the typical crushing process using this equipment?

A: During operation, raw materials are fed into the machine, where they encounter a fast-moving rotor. The materials resulting impact against anvils and cascading material flow ensures efficient reduction and shaping, producing finely graded products.Q: How should the crusher be maintained to ensure optimal performance?

A: Routine visual inspections, timely replacement of wear parts, and calibration of the PLC control system are recommended. Its stainless steel body makes cleaning and upkeep straightforward, contributing to low-cost, long-term operation.Q: What warranty and support options are available for purchasers?

A: Each unit comes with a one-year warranty, covering manufacturer defects and ensuring peace of mind. Exporters, manufacturers, and suppliers in India benefit from responsive support and after-sales service.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese